SEEFOR 13(2): 107-113

Article ID: 2213

DOI: https://doi.org/10.15177/seefor.22-13

ORIGINAL SCIENTIFIC PAPER

Energy Properties of 22 Timber Species from Oaxaca, Mexico

Faustino Ruiz-Aquino1, María Elena Jiménez-Mendoza1, Mario Enrique Fuente-Carrasco1, Wenceslao Santiago-García1, Mario Ernesto Suárez-Mota1, Ciro Aquino-Vásquez1, José Guadalupe Rutiaga-Quiñones2,*

(1) Instituto de Estudios Ambientales, Universidad de la Sierra Juárez, Avenida Universidad S/N, Ixtlán de Juárez, Oaxaca C.P. 68725, México;

(2) Facultad de Ingeniería en Tecnología de la Madera, Universidad Michoacana de San Nicolás de Hidalgo, Av. Fco. J. Múgica S/N, Col. Felicitas del Rio, Morelia, Michoacán C. P. 58040, México

Citation: Ruiz-Aquino F, Jiménez-Mendoza ME, Fuente-Carrasco ME, Santiago-García W, Suárez-Mota ME, Aquino-Vásquez C, Rutiaga-Quiñones JG, 2022. Energy Properties of 22 Timber Species from Oaxaca, Mexico. South-east Eur for 13(2): 107-113. https://doi.org/10.15177/seefor.22-13.

Received: 25 Jul 2022; Revised: 1 Nov 2022; Accepted: 16 Nov 2022; Published online: 10 Dec 2022

Cited by: Crossref Google Scholar

Abstract

The potential use of forest species as fuels depends on their energy quality. However, in rural communities in developing countries, fuelwood is still an energy source without any technical study evaluating its energetic characteristics. Therefore, this study aimed to analyze the energetic characteristics of 22 forest species from four communities in the state of Oaxaca, Mexico. The basic wood density, proximal analysis, and high heating value were evaluated. As a result of the analysis, the fuel number (FN) is proposed as a measure of the energy quality of biomass fuels in the form of firewood. FN considers the basic wood density, the fixed carbon, and the high heating value of each species. Wood basic density ranged from 0.472 g·cm-3 for Pinus pseudostrobus to 0.814 g·cm-3 for Dodonaea viscosa, fixed carbon ranged from 4.74% to 21.27% for Liquidambar styraciflua and Quercus rugosa, respectively, and high heating value from 18.33 MJ·kg-1 to 22.07 MJ·kg-1 for Liquidambar styraciflua and Pinus leiophylla, respectively. Classifying wood according to FN, in decreasing order, Quercus rugosa stands out as the best wood (66.97%), followed by Liquidambar styraciflua (39.52%). Regarding the fuel value index, the nine pine species showed the highest values (27.32 to 77.76). The FN provides a measure of the quality of biomass fuels in the form of firewood, and can be evaluated by easily measured variables.

Keywords: basic wood density; proximate analysis; high heating value; fuel number; fuel value index

INTRODUCTION

The use of wood as fuel started when humanity discovered how to make fire for cooking or heating (Ramos et al. 2016). Currently, wood is an essential raw material in the energy supply for many sectors in the world, such as industrial, commercial, transportation, and household. In rural communities in developing countries, biomass from forests is used as an energy source for cooking, both due to economic and cultural conditions (Sierra-Vargas et al. 2014). In addition, its use contributes significantly to climate change mitigation (de Oliveira et al. 2022).

Despite efforts to control biomass energy use, biomass remains the most attractive resource for local populations and, therefore, continues to be of great importance (Massuque et al. 2021). Globally, it is estimated that about half of the population uses plant or animal biomass as the primary source of energy for domestic use, where firewood is the primary fuel (Aguirre-Cortés et al. 2018, CONABIO 2020). The global consumption of firewood is estimated at over 1.5 billion m3 per year. Europe uses more than 90 million m3 of fuelwood per year (Parikka 2004), with an increase between 1992 and 2006 of 39 million m3 (Buongiorno et al. 2012). In Mexico, in 2018, 1,069,380 m3 of timber production was designated for energy use (SEMARNAT 2018). In addition, 11% of households use firewood or charcoal, which represents 40% of the total energy used (INEGI 2018).

The wood used as fuel must be evaluated to determine its suitability for bioenergy production (Lachowicz et al. 2018). The most important parameters to evaluate include volatile matter, ash content, fixed carbon, calorific value, moisture content, basic density, and chemical composition (Choi et al. 2014, de Paula Protásio et al. 2019). This study mainly evaluates the energetic wood characteristics from 22 species collected in the forests of Oaxaca, Mexico, and proposes a number to rank the quality of biomass fuels.

MATERIALS AND METHODS

Study Area

Woody biomass was collected in different areas of forest communities in the state of Oaxaca, Mexico: Ixtlán de Juárez, Oaxaca (17°20' N and 96°29' W), San Sebastián Coatlán, Miahutlán, Oaxaca (16°12'41.6" N and 96°49'15.9" W), Santa María Tlahuitoltepec, Mixe, Oaxaca (17°03' N and 95°58' W) and San Juan Metaltepec, Mixe, Oaxaca (17°10' N and 95°54' W).

Tree Selection and Sample Preparation

Two trees per species, healthy, without bifurcation, and representative of the study area, were selected and harvested. A directional felling was applied to the trees with an Oleo-Mac GS 370® chainsaw. A 1 m long log close to the root was taken from each tree, and a 2 cm slice was cut from each side (Ruiz-Aquino et al. 2019). To determine the energetic characteristics, the material was chipped, and ground in a Wiley-type mill; the material that was retained in the 40 mesh was used (Rutiaga-Quiñones et al. 2020).

Determining the Basic Wood Density

From each slice, cubes of 2 cm per side were cut with a KNOVA KN SCM-10A® band saw. The fresh volume of each cube was determined by the immersion method, determining the mass of water displaced by a wooden cube when immersed in water (Figure 1), the mass in grams being numerically equal to the volume in centimeters (Test method B- Volume by Water Immersion (ASTM 2007a)). Subsequently, once the cubes were in their anhydrous state, their basic wood density (BWD) was calculated as the ratio of the anhydrous weight and the fresh green volume (ASTM 2007a).

![]() Figure 1. Determination of fresh volume by the immersion method.

Figure 1. Determination of fresh volume by the immersion method.

Proximal Analysis

Ash content and volatile matter (VM) content were calculated using ASTM D1102-84 (2007b), and ASTM E872-82 (2013), respectively. Additionally, fixed carbon (FC) was calculated as the sum of ash and volatile matter subtracted from 100 (ASTM 2006). All percentages were calculated taking as reference the anhydrous weight of the samples.

High Heating Value

A 1341 flat jacket calorimeter (Parr, USA), equipped with a digital thermometer (Parr, 6775), ignition unit (Parr, 2901), and calorimetric pump (Parr, 1108) was used to calculate the high heating value (HHV), in accordance with ASTM E 711-87 (2004).

Fuel Number

The use of a number is proposed to rank the quality of biomass fuels. As independent variables, three parameters are considered as good indicators of energy quality: BWD, FC, and HHV (Demirbaş and Demirbaş 2009). For the development of the Fuel Number (FN), maximum values of each of the independent variables were taken. In the case of basic density, the cell wall density of 1.53 g·cm-3 is practically constant for all woods (Desch and Dinwoodie 1981, Usta 2003). For fixed carbon, it is considered that the higher it is, the better the fuel quality is. In addition, fixed carbon is an important generator of heat during combustion (Kongprasert et al. 2019); different studies agree that the value of fixed carbon in biomass fuels in the form of firewood or densified, does not exceed 30% (Uceda 1984, Vassilev et al. 2010, Ruiz-Aquino et al. 2019, Ramírez-Ramírez et al. 2021, 2022). In the HHV, lignin (25.58 MJ·kg-1) was taken as the maximum value because, in general, the HHV of biomass fuels increases with lignin content and is highly correlated (Demirbaş 2001, 2002, 2003). If we consider hypothetical data for fuel with the best characteristics outlined above, then FN takes a maximum value of 100%. Under this premise, it is relatively simple to rank the quality of biomass fuels, considering that the higher the FN, the better the fuel quality.

Fuel Value Index

In the present study, a comparison has also been made with the Fuel Value Index (FVI) proposed by Bhatt and Todaria (1992), where calorific value and density are considered positive characters and ash content is a negative parameter (Equation 1):

(1)

(1)

where HHV is high heating value (MJ·kg-1), BD is basic wood density (g·cm-3), and A is ash content (%).

All analyses were performed with five replicates, and the mean value and standard deviation have been reported. No software was used to calculate these values.

RESULTS AND DISCUSSION

Basic Density

Table 1 summarizes the mean values and standard deviation in parentheses for the 22 studied tree species in the study; thirteen belong to the broadleaved hardwood and nine to the conifer group. In the broadleaved hardwoods group, the basic wood density varies from 0.475 g·cm-3 for Liquidambar styraciflua to 0.814 g·cm-3 for Dodonaea viscosa. Concerning oaks, the results are within the defined interval (0.543 to 0.889 g·cm-3) reported by different authors (De la Paz Pérez-Olvera and Dávalos-Sotelo 2008, Herrera-Fernández 2013, Ruiz-Aquino et al. 2015, Herrera-Fernández et al. 2017). Based on the classification by Sotomayor (2005), Dodonaea viscosa is classified as very high-density wood, while the five oak species are classified in the category of high density. In the case of conifers, the obtained values ranged from 0.472 g·cm-3 (Pinus pseudostrobus) to 0.600 g·cm-3 (P. patula), the nine species were classified as medium density woods (0.401 to 0.600 g·cm-3) proposed by Sotomayor (2005). In general, the BWD values for pine wood are in accordance with data previously reported by Peña and Rojas (2006) and Sotomayor (2005). The basic density of wood is a physical property that influences biomass combustion processes (Demirbaş and Demirbaş 2009). Kumar et al. (2010) found that higher basic density increases the calorific value of wood due to the energy contained per unit of volume. This coincides with findings by Ruiz-Aquino et al. (2015), who mention that high-density woods are preferred as fuels in a rural community in Oaxaca, Mexico. BWD and extractives content are characteristics responsible for providing high energy density, longer duration, and intensity of combustion, which are important characteristics for choosing the type of fuelwood (Massuque et al. 2020).

![]() Table 1. Basic wood density, proximate analysis, and high heating value of 22 tree species.

Table 1. Basic wood density, proximate analysis, and high heating value of 22 tree species.

Proximal Analysis

Fuel's volatile matter is the portion of condensable and non-condensable gases and vapors which are released when the fuel is heated for a specific time and at specific temperature (Basu 2018). Volatile matter levels are inversely proportional to fixed carbon content (Pereira et al. 2012). According to Ragland et al. (1991), the volatile content for wood ranges from 70% to 90%, relative to the anhydrous weight of the sample, and can be subdivided into light hydrocarbons, tar, carbon monoxide, carbon dioxide, hydrogen, and moisture.

The volatile material content in broadleaves varied from 76.60% for Quercus rugosa to 94.70% for Liquidambar styraciflua (Table 1), while in the conifer group, the variation was from 84.56% to 94.82% for Pinus lawsonii and P. rudis, respectively. In general, the values found for hardwoods coincide with those reported by different authors. For acacia species, a range of 75.30% to 86.50% has been reported (Agostinho-Da Silva et al. 2014, Eloy et al. 2015, Apolinar et al. 2016). Alnus jorullensis presented 82.767 %, like that reported by Ruiz-Aquino et al. (2019), and 82.61% was reported for Alnus acuminata. The results for conifers are close to values reported for pine wood (78.9% to 89.8%) (Rutiaga-Quiñones et al. 2020).

Ash content in hardwoods varied from 0.49% for Alnus jorullensis to 4.51% for Acacia pennatula, and in conifers from 0.16% for Pinus devoniana to 0.39% for P. patula. Out of the 13 hardwoods species in the present study, 12 were in the content range (1% to 3.4%) according to Gutiérrez-Acosta et al. (2021), except Acacia pennatula, which presented the highest ash content (4.51%). Regarding the four pine species (P. patula, P. rudis, P. douglasiana and P. ayacahuite), they were within the ash range (0.27% to 0.95%) referred by Rutiaga Quiñones et al. (2020). On the other hand, Pinus pseudostrobus, P. leiophylla, P. hartwegii, P. lawsonii, and P. devoniana were positioned within the range (0.13% to 0.23%) for bioenergy use reported by Pintor-Ibarra et al. (2017). All conifers in this study were within the range (0.1% to 1.1%) reported for pine sawdust (Ramírez-Ramírez et al. 2021). In general, ash content in conifers is lower than in broadleaved hardwoods, which coincides with the study by Gutiérrez-Acosta et al. (2021). The ash content in biomass influences fuel quality and higher content decreases the calorific value (Demirbaş and Demirbaş 2009, Klašnja et al. 2013, Martínez-Pérez et al. 2015, Ngangyo-Heya et al. 2016, Ruiz-Aquino et al. 2019). In combustion equipment (for example, stoves, ovens, furnaces, boilers, among others), it is preferable to use firewood with lower ash content because the containing minerals cause corrosion and potential problems to the equipment (Massuque et al. 2020).

Fixed carbon is the solid carbonaceous residue from the release of volatiles from biomass (McKendry 2002). It is related to the amount of ash and volatiles; thus, a higher amount of these components is reflected in a lower concentration of fixed carbon (Ruiz-Aquino et al. 2019). The fixed carbon content in the wood of the species studied (Table 1) ranged from 4.74% (Liquidambar styraciflua) to 21.27% (Quercus rugosa), and in conifer species from 4.88% (Pinus rudis) to 15.27% (P. lawsonii). All 22 tree species in the present study suit well within the range (6.5% to 26.3%), as reported for 28 wood and woody biomass samples by Vassilev et al. (2010). In our study, Liquidambar styraciflua has the highest volatile matter, and, therefore, it is considered the species that shows the lowest amount of fixed carbon.

High Heating Value

The HHV in hardwoods ranged from 18.33 MJ·kg-1 for Liquidambar styraciflua to 21.06 MJ·kg-1 for Dodonaea viscosa, and in conifers from 18.83 MJ·kg-1 for Pinus lawsonii to 22.07 MJ·kg-1 for P. leiophylla. The HHV of 12 studied hardwoods was within the range (19 to 21 MJ·kg-1) as reported for hardwoods by Mark et al. (1985), while only four conifers were below the mentioned range (20-22 MJ·kg-1). The slightly higher HHV values of conifers can be explained by the higher extractive contents and lignin in conifer wood (Ragland et al. 1991).

Fuel Number

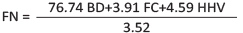

Taking the values considered as the maximum for the parameters: basic density (BWD = 1.53 g·cm3), fixed carbon (FC = 30%), and higher calorific value of lignin (HHV = 25.58 MJ·kg-1), the FN was calculated as the average of the mentioned parameters (Equation 2):

(2)

(2)

where BD is basic density (g·cm-3) BWD, FC is Fixed carbon content (%), and HHV is high heating value (MJ·kg-1).

Table 2 presents a comparison between the fuel number (FN) calculated and proposed in the study, and the fuel value index (FVI) proposed by Bhatt and Todaria (1992).

![]() Table 2. Fuel number (FN) and fuel value index (FVI)* for 22 timber species..

Table 2. Fuel number (FN) and fuel value index (FVI)* for 22 timber species..

Classifying the tree species’ wood based on FN in decreasing order, Quercus rugosa stands out as the best wood (66.97%), followed by Liquidambar styraciflua (39.52%). It can be observed that except for Quercus candicans, which may be due to its low fixed carbon content (Table 1), oak species are considered as most important. This hierarchy is congruent with the findings by Ramírez-López et al. (2012), who found that, in eight social communities in Chiapas, Mexico, oak firewood is preferred due to its heating quality. Similarly, Soares (2006) and Ruiz-Aquino et al. (2015) indicate that the most preferred fuel species belong to the Quercus genus. The preference for the use of oak wood as fuel lies in the high basic density of the wood, high fixed carbon content, high calorific value, and low ash content, characteristics that influence energy quality the most (Abbot et al. 1997). On the contrary, the low FN of Liquidambar styraciflua is explained by the high amount of volatiles (94.7%), its medium basic density (0.475 g·cm-3), and low fixed carbon content (4.74%), being the species with the lowest calorific value (18.33 MJ·kg-1), in comparison with the other studied species. The second most important species is Dodonaea viscosa, also preferred as a fuelwood in an indigenous community in Oaxaca due to its high BWD, high fixed carbon content, high calorific value, and low ash content coupled with easy ignition properties (Silva-Aparicio et al. 2018).

Fuel Value Index

Regarding the FVI, the highest value was found in Pinus devoniana (77.76) and the lowest in Acacia pennatula (2.63). The nine pine species showed the highest FVI values (27.32 to 77.76). However, in practice, this fuelwood is quickly consumed, and is not preferred as a good material for certain uses, such as cooking food (Ramírez-López et al. 2012, Morales-Máximo et al. 2019). The high FVI values in pine wood are more influenced by how it is calculated, i.e., the product of the calorific value and BWD is more significant, while fixed carbon is not considered. Conifers have a higher calorific value than hardwoods due to the higher amount of lignin; however, the quality of fuelwood should not be ranked based on HHV alone. In the RFN, the three parameters (HHV, BWD and FC) have the same importance and the ranking results are congruent with the preference of users (Ramírez-López et al. 2012, Ruiz-Aquino et al. 2015).

The FN provides a measure of the quality of biomass fuels in the form of firewood. However, fuel quality is currently taking a back seat due to deforestation and land-use change, causing primary fuelwood users to use species that are closer in proximity to decrease transportation costs (Deka et al. 2002, Ramírez-López et al. 2012).

CONCLUSION

The basic wood density varied in a range from 0.475 g·cm-3 for Liquidambar styraciflua to 0.814 g·cm-3 for Dodonaea viscosa. Within this range, the five species of oaks are classified as having high wood density, ideal for their use as fuels. On average, coniferous firewood presented lower ash content, an indispensable attribute for its use as densified fuel. The high heating value of conifers was, on average, higher than that of hardwoods. Good fuel quality was verified with the FN, given the combination of wood density, high calorific value, and fixed carbon content. Based on the FN, four Quercus species indicate better fuel quality. The nine pine species showed the highest values for FVI (27.32 to 77.76), but in practice, they are not favorable for use by the local communities.

Author Contributions

FRA, MEJM, JGRQ conceived and designed the research; FRA, MEJM carried out the field and laboratory measurements; MEFC, WSG, MESM, CAV processed the data; FRA, MEJM, JGRQ, MEFC, WSG, MESM, CAV drafted the manuscript, and wrote the manuscript. All authors read and approved the final manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

REFERENCES

Abbot P, Lowore J, Khofi C, Werren M, 1997. Defining firewood quality: A comparison of quantitative and rapid appraisal techniques to evaluate firewood species from a Southern African Savanna. Biomass Bioenerg 12(6): 429-437. https://doi.org/10.1016/S0961-9534(96)00084-0.

Agostinho-Da Silva D, Otomar-Caron B, Sanquetta CR, Behling A, Scmidt D, Bamberg R, Eloy E, Dalla-Corte AP, 2014. Equations for estimating gross calorific value of wood from four tree species. Rev Chapingo Ser Cie 20(2): 177-186. https://doi.org/10.5154/r.rchscfa.2013.09.035.

Aguirre-Cortés E, López-Martínez JO, Vargas-Larreta B, Pat-Fernández JM, Macario-Mendoza P, 2018. Preferencias de uso de leña en un paisaje cultural en el sur de México Rev Chapingo Ser Cie 24(2): 147-160. https://doi.org/10.5154/r.rchscfa.2017.08.053.

Apolinar HF, Honorato-Salazar JA, Colotl GH, 2016. Caracterización energética de la madera de Acacia pennatula Schltdl. & Cham. y Trema micrantha (L.) Blume. Rev Mex Cienc Forestales 8(39): 71-81. https://doi.org/10.29298/rmcf.v8i39.44.

ASTM E 711-87, 2004. Standard Test Method for Gross Calorific Value of Refuse-Derived Fuel by the Bomb Calorimeter. ASTM International, West Conshohocken, PA, USA.

ASTM E870-82, 2006. Standard test methods for analysis of wood fuels. ASTM International, West Conshohocken, PA, USA.

ASTM D2395-07, 2007a. Standard Test Methods for Specific Gravity of Wood and Wood-Based Materials. ASTM International, West Conshohocken, PA, USA.

ASTM D1102-84, 2007b. Standard test method for ash in wood. ASTM International, West Conshohocken, PA, USA.

ASTM E872-82, 2013. Standard test method for volatile matter in the analysis of particulate wood fuels. ASTM International, West Conshohocken, PA, USA.

Basu P, 2018. Biomass Gasification and Pyrolysis and Torrefaction. Practical Design and Theory. 3rd edn. Academic Press, Burlington, USA. 557 p. https://doi.org/10.1016/C2016-0-04056-1.

Bhatt BP, Todaria NP, 1992. Fuelwood characteristics of some mountain trees and shrubs. Commonw Forest Rev 71(3/4): 183–185.

Buongiorno J, Zhu S, Raunikar R, Prestemon P, 2012. Outlook to 2060 for world forests and forest industries: a technical document supporting Forest Service 2010 RPA assessment (Vol. 151). US Department of Agriculture, Forest Service, Southern Research Station. 119 p.

Choi HL, Sudiarto SIA, Renggaman A. 2014. Prediction of livestock manure and mixture higher heating value based on fundamental analysis. Fuel 116: 772-780. https://doi.org/10.1016/j.fuel.2013.08.064.

CONABIO, 2020. Combustible. Comisión Nacional para el Conocimiento y Uso de la Biodiversidad, Cd. de México, México. Available online: https://www.biodiversidad.gob.mx/diversidad/combustible (5 June 2022).

Deka D, Saikia P, Konwer D, 2007. Ranking of Fuelwood Species by Fuel Value Index. Energ Source Part A 29(16): 1499-1506. https://doi.org/10.1080/15567030600820476.

De la Paz Pérez-Olvera C, Dávalos-Sotelo R, 2008. Algunas características anatómicas y tecnológicas de la madera de 24 especies de Quercus (encinos) de México. Madera Bosques 14(3): 43-80. https://doi.org/10.21829/myb.2008.1431206.

de Oliveira PRS, Trugilho PF, de Oliveira TJP, 2022. Briquettes of acai seeds: characterization of the biomass and influence of the parameters of production temperature and pressure in the physical-mechanical and energy quality. Environ Sci Pollut Res 29: 8549-8558. https://doi.org/10.1007/s11356-021-15847-6.

de Paula Protásio T, Scatolino MV, de Araújo ACC, de Oliveira AFCF, de Figueiredo ICR, de Assis MR, Trugilho PF, 2019. Assessing Proximate Composition, Extractive Concentration, and Lignin Quality to Determine Appropriate Parameters for Selection of Superior Eucalyptus Firewood. Bioenerg Res 12: 626-641. https://doi.org/10.1007/s12155-019-10004-x.

Demirbaş A, 2001. Relationships between lignin contents and heating values of biomass. Energ Convers Manage 42(2): 183-188. https://doi.org/10.1016/S0196-8904(00)00050-9.

Demirbaş A, 2002. Relationships between heating value and lignin, moisture, ash and extractive contents of biomass fuels. Energ Explor Exploit 20(1): 105-111. https://doi.org/10.1260/014459802760170420.

Demirbaş A, 2003. Relationships between heating value and lignin, fixed carbon, and volatile material contents of shells from biomass products. Energ Source 25(7): 629-635. https://doi.org/10.1080/00908310390212336.

Demirbaş T, Demirbaş C, 2009. Fuel properties of wood species. Energ Source Part A 31(16): 1464-1472. https://doi.org/10.1080/15567030802093153.

Desch HE, Dinwoodie JM, 1981. Timber: Its Structure, Properties and Utilization. 6th edition. MacMillan Press Ltd, London, UK. 410 p.

Eloy E, da Silva DA, Caron BO, de Souza VQ, 2015. Capacidade energética da madeira e da casca de acácia-negra em diferentes espacamentos. Pesqui Florest Bras 35(82): 163-167. https://doi.org/10.4336/2015.pfb.35.82.606.

Gutiérrez-Acosta JM, Orihuela-Equihua R, Pintor-Ibarra LF, González-Ortega N, Hernández-Solís J, Ruiz-Aquino F, Navarrete-García MA, Rutiaga-Quiñones JG, 2021. On the Basic Chemical Composition of Selected Biomass Types from Four Regions of Mexico, for Bioenergetic Purposes. BioResources 16(3): 5694-5705. https://doi.org/10.15376/biores.16.3.5694-5705.

Herrera-Fernández AC, 2013. Determinación de la densidad en madera, poder calorífico y composición química en corteza y madera de seis especies de latifoliadas. MSc. Thesis, Universidad Michoacana de San Nicolás de Hidalgo, Facultad de Ingeniería en Tecnología de la Madera, Morelia, Michoacán, México, 162 p.

Herrera-Fernández AC, Carrillo-Parra A, Pedraza-Bucio FE, Correa-Méndez F, Herrera-Bucio R, López-Albarrán P, Rutiaga-Quiñones JG, 2017. Densidad, composición química y poder calorífico de la madera de tres especies de encino (Quercus candicans, Q. laurina y Q. rugosa). Ciencia Nicolaita 72: 136-154.

INEGI, 2018. Encuesta Nacional sobre Consumo de Energéticos en Viviendas Particulares (ENCEVI). Instituto Nacional de Estadística y Geografía, México, 100 p. Available online: https://www.inegi.org.mx/contenidos/programas/encevi/2018/doc/encevi2018_presentacion_resultados.pdf (10 March 2020).

Klašnja B, Orlović S, Galić Z, 2013. Comparison of Different Wood Species as Raw Materials for Bioenergy. South-east Eur for 4(2): 81-88. https://doi.org/10.15177/seefor.13-08.

Kongprasert N, Wangphanich P, Jutilarptavorn A, 2019. Charcoal briquettes from Madan Wood Waste as an Alternative Energy in Thailand. Procedia Manuf 30: 128-135. https://doi.org/10.1016/j.promfg.2019.02.019.

Kumar R, Pandey KK, Chandrashekar N, Mohan S, 2010. Effect of tree-age on calorific value and other fuel properties of Eucalyptus hybrid. J For Res 21(4): 514-516. https://doi.org/10.1007/s11676-010-0108-x.

Lachowicz H, Sajdak M, Paschalis-Jakubowicz P, Cichy W, Wojtan R, Witczak M, 2018. The Influence of Location, Tree Age and Forest Habitat Type on Basic Fuel Properties of the Wood of the Silver Birch (Betula pendula Roth.) in Poland. Bioenerg Res 11: 638-651. https://doi.org/10.1007/s12155-018-9926-z.

Mark HF, Bikales NM, Overberger CG, Menges G, Kroschwitz JI, 1985. Encyclopedia of Polymer Science and Engineering. 2nd edn, Wiley-Interscience. 850 p.

Martínez-Pérez R, Pedraza-Bucio FE, Orihuela-Equihua R, López-Albarrán P, Rutiaga-Quiñones JG, 2015. Calorific value and inorganic material of ten mexican wood species. Wood Res-Slovakia 60(2): 281-292.

Massuque J, De Assis MR, Trugilho PF, 2020. Characterization of Miombo species used by rural communities as fuelwood in Northern Mozambique. Energ Source Part A 1-10. https://doi.org/10.1080/15567036.2020.1815910.

Massuque J, Matavel CF, Trugilho PF, 2021. Outlook for the biomass energy sector in Mozambique: Policies and their challenges. J Energy South Africa 32(4): 1-10. https://doi.org/10.17159/2413-3051/2021/v32i4a11936.

McKendry P, 2002. Energy production from biomass (part 1): overview of biomass. Bioresource Technol 83(1): 37-46. https://doi.org/10.1016/S0960-8524(01)00118-3.

Morales-Máximo M, Castro-Sánchez FJ, Rutiaga-Quiñones JG, 2019. Estudio socioeconómico para la evaluación de biocombustibles sólidos: eficiencia energética y alterna en la comunidad de San Francisco Pichátaro, Michoacán, México. Int Energy Conf 2: 577-582.

Ngangyo-Heya M, Foroughbahchk-Pournavab R, Carrillo-Parra A, Rutiaga-Quiñones JG, Zelinski V, Pintor-Ibarra LF, 2016. Calorific Value and Chemical Composition of Five Semi-arid Mexican Tree Species. Forests 7(3): 1-12. https://doi.org/10.3390/f7030058.

Parikka M, 2004. Global biomass fuel resources, Biomass and Bioenergy 27: 613-620. https://doi.org/10.1016/j.biombioe.2003.07.005

Peña SV, Rojas IM, 2006. Tecnología de la Madera. 3rd edn. Mundi-Prensa, Madrid, España, 685 p.

Pereira BLC, Oliveira AC, Carvalho AMML, Santos LC, Vital RB, 2012. Quality of wood and charcoal from Eucalyptus clones for Ironmaster Use. International Journal of Forestry Research 2012: 523025. https://doi.org/10.1155/2012/523025.

Pintor-Ibarra LF, Carrillo-Parra A, Herrera-Bucio R, López-Albarrán P, Rutiaga-Quiñones JG, 2017. Physical and chemical properties of timber byproducts from Pinus leiophylla, P. montezumae and P. pseudostrobus for a bioenergetic use. Wood Res-Slovakia 62(6): 849-861.

Ragland KW, Aerts DJ, Baker AJ, 1991. Properties of wood for combustion analysis. Bioresource Technol 37(2): 161-168. https://doi.org/10.1016/0960-8524(91)90205-X.

Ramírez-López JM, Ramírez-Marcial N, Cortina-Villar HS, Castillo-Santiago MA, 2012. Déficit de leña en comunidades cafetaleras de Chenalhó, Chiapas. Ra Ximhai 8(3): 27-39.

Ramírez-Ramírez MA, Carrillo-Parra A, Ruiz-Aquino F, Hernández-Solís JJ, Pintor-Ibarra LF, González-Ortega N, Orihuela-Equihua R, Carrillo-Ávila N, Rutiaga-Quiñones JG, 2022. Evaluation of Selected Physical and Thermal Properties of Briquette Hardwood Biomass Biofuel. Bioenerg Res 15: 1407-1414. https://doi.org/10.1007/s12155-022-10391-8.

Ramírez-Ramírez MA, Carrillo-Parra A, Ruíz-Aquino F, Pintor-Ibarra LF, González-Ortega N, Orihuela-Equihua R, Carrillo-Ávila N, Luján-Álvarez C, Rutiaga-Quiñones JG, 2021. Valorization of briquettes fuel using Pinus spp. sawdust from five regions of Mexico. BioResources 16(2): 2249-2263. https://doi.org/10.15376/biores.16.2.2249-2263.

Ramos FD, Díaz MS, Villar MA, 2016. Biocombustibles. Ciencia Hoy 25(147): 69-73.

Ruiz-Aquino F, González-Peña MM, Valdez-Hernández JI, Revilla US, Romero-Manzanares A, 2015. Chemical characterization and fuel properties of wood and bark of two oaks from Oaxaca, Mexico. Ind Crops Prod 65: 90-95. https://doi.org/10.1016/j.indcrop.2014.11.024.

Ruiz-Aquino F, Ruiz-Ángel S, Santiago-García W, Fuente-Carrasco ME, Sotomayor-Castellanos JR, Carrillo-Parra A, 2019. Energy characteristics of wood and charcoal of selected tree species in Mexico. Wood Res-Slovakia 64(1): 71-82.

Rutiaga-Quiñones JG, Pintor-Ibarra LF, Orihuela-Equihua R, González-Ortega N, Ramírez-Ramírez MA, Carrillo-Parra A, Carrillo-Ávila N, Navarrete-García MA, Ruiz-Aquino F, Rangel-Méndez JR, Hernández-Solís J, Luján-Álvarez C, 2020. Characterization of Mexican waste biomass relative to energy generation. BioResources 15(4): 8529-8553 https://doi.org/10.15376/biores.15.4.8529-8553.

SEMARNAT, 2018. Anuario Estadístico de la producción forestal, Secretaría de Medio Ambiente y Recursos Naturales, México, 298 p. Available online: https://www.gob.mx/semarnat/documentos/anuarios-estadisticos-forestales (15 June 2021)

Sierra-Vargas FE, Guerrero-Fajardo CA, Mejía-Barragán F, 2014. Determinación de la eficiencia de la cocción con leña en las veredas de Usme, Bogotá. Ingeniería Mecánica 17(2): 185-194.

Silva-Aparicio M, Castro-Ramírez AE, Perales-Rivera HR, 2018. Áreas voluntarias de conservación y la extracción de leña en núcleos agrarios de Oaxaca. Ecosistemas y Recursos Agropecuarios 5(15): 435-449. https://doi.org/10.19136/era.a5n15.1743.

Soares D, 2006. Género, leña y sostenibilidad: el caso de una comunidad de los Altos de Chiapas. Economía, Sociedad y Territorio 21: 151-175.

Sotomayor CJR, 2005. Características mecánicas y clasificación de la madera de 150 especies mexicanas. Facultad de Ingeniería en Tecnología de la Madera. Universidad Michoacana de San Nicolás de Hidalgo 1(1): 1-24.

Uceda M, 1984. Determinación del poder calorífico de 20 especies forestales de la amazonia peruana. Revista Forestal del Perú 12(1-2): 1-15.

Usta İ, 2003. Comparative study of wood density by specific amount of void volume (porosity). Turk J Agric For 27(1): 1-6.

Vassilev SV, Baxter D, Andersen LK, Vassileva CG, 2010. An overview of the chemical composition of biomass. Fuel 89(5): 913-933. https://doi.org/10.1016/j.fuel.2009.10.022.

© 2022 by the Croatian Forest Research Institute. This is an Open Access paper distributed under the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/by/4.0).